Hello, Sergiu!

On Canon MP 250 devices, a similar problem arises from the advance of the system when the fill level of the absorber for processed ink reaches 95%.

To continue the work, you must press the Resume/Cancel button.

However, if the absorber level reaches 100%, the MFP is blocked and cannot be processed, and the water level will not be reset.

To make things clearer, it is necessary to identify the device, the name of the absorber, and why it is being used.

Today's inkjet printers produce drying ink for each other. Apparently, the ink also dries easily in the nozzles of the other printer head. To avoid clogging of the tool head and ensure uninterrupted flow, printers use special mechanisms Then turn on the pump to dissolve a small amount of ink. The selected ink is placed in a special container that contains the material that is being collected. This capacity is called an absorber (or diaper).

The adhesive material in the absorber is a great resource of usefulness. When the clay material is filled with selected ink, the capacity will be refilled. To prevent this from overfilling, the absorber should be equipped with a disinfectant that contains the amount of ink. This liquid cleaner itself responds when the ink reaches the specified value and blocks the printer’s operation.

To continue the operation of the printer, it is necessary to perform servicing, wash the diaper and reset the absorber liquid to zero.

In your case, the system told you about filling the absorber with E8 milk. Oskolki, pardon given vinyl first, there is no need to physically wash the absorber when disassembling the device. As practice shows, when first used as a remedy after short-term use of the printer, the material that is absorbed is not yet heavily contaminated and does not affect the robotic device.

In this case, it is enough to reset the absorber level.

For the Canon MP 250 printer, you can download the absorber cleaner using the additional service program ServiceTool_V2000.

You can download the program here:

Sequence of actions to reset the medical device:

1. Install the service program ServiceTool_V2000.

2. Turn off the device with the button (do not connect the cord, the device must be connected to a computer via USB).

3. Press and press the Resume button, indicated by the trikutnik near the stake.

4. Without releasing the Resume button, press the УВИМК button (keep both buttons pressed).

5. When the indicator lights up, release Resume (ON pressed button) and press twice (on the pressed surface the printer reacts by alternating indications: at the first press from green to yellow, at the other - from yellow to green), after which button. The indicator blinks green several times, then glows green steadily.

If instead of the green one, which constantly burns, the yellow indicator flashes, or blinks from the green one, the printer has an additional reset, which must be removed before working with the service program. What kind of mercy is it - you can find out more here:

If the USB cable is plugged in, you must connect it before starting ServiceTool. The computer will detect a new printer and register and install the driver - be sure

6. Launch the ServiceTool_V2000 program.

7. In the program window, in the “Clear ink Counter” section, click “Main” (if necessary, “Platen”) - the doctor will reset to “0”

8. Close ServiceTool, turn on the printer, turn on USB cable(as needed).

Remove from the “Printers and Faxes” folder the printer “copy 1”, which is installed in the service mode (as already installed).

The owners of jet printers and multifunctional printers came to grips with such concepts as the refurbishment of the absorber. Or it is also called a diaper refill. It is likely that one day a notification will appear on the PC or on the printer display, “Process X will appear until service center»

This is the case with inkjet printers, so that in order to ensure that the ink is kept clean, the printer “pours” some of the ink…. into the toilet... well, into our absorber. Every inkjet printer has this diaper. This type of ink is a special medium that contains a special rich spherical fibrous material that is designed to absorb the high strength of ink.

And this absorber is outside the black hole

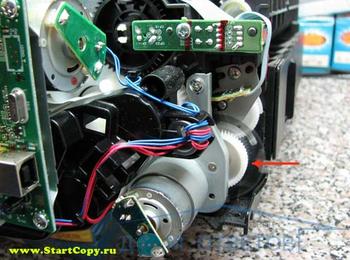

In order to prevent the ink from getting wet, the printer, when turned on, dispenses a small amount of ink into a special tray, and a vacuum pump pumps the ink through an elastic tube into the material it is collecting. This cleaning process is carried out every hour of the document through the final period. Also, a great deal of ink will be released into the diaper if you use a Primus to clean the blower head or clean the nozzles. It’s worth remembering the injection procedure at the doctor’s office. Before giving the injection, the doctor directs the head to the head and lightly presses the piston, exfoliating part of the face and extruding from the head.

How does the printer know when the diaper is refilled?

In fact, there are no sensors in the printer that track the level of ink in the absorber. Printers install the firmware of the printer or MFP, which signals a change after a certain period of time. If you really want, the absorber can still accommodate a triple portion of ink. On some Epson models, I noted that this is due to the amount of cleaning of the mechanical head. Anyway, in any case, the field workers started talking about those, in order to get ahead of the koristuvach about the upcoming black flood.

Why bother when there was a notification about renewing the printer absorber?

Here, for a number of nobles, a major problem arises. If you rarely work and this information has appeared to you after one or two uses of the printer, then you can simply reset the diaper cleaner. You can create the required service program for your printer model yourself. Or bring it to the SC. There you can get money from a doctor for pennies. And then wash the absorber capacity as soon as possible. The ink is not sticking out of the printer.

Another way to use the active core of the string technology is with an external absorber. Tobto. By means of a clumsy way of inserting into the design of the printer, the tube from the pump is brought out and a container is attached to it.

In this case, the printer will immediately lose ink. And there is no threat that once black was splashed under the printer. And with the appearance of the re-installation of the absorber, you will need to discard it using the service program. It’s true that if you work with “crooked” hands, then picking up the ink spilled on the table will not be unique.

Axis and everything I wanted to say about absorber in inkjet printers.

Strumen technology often uses a device called an absorber. What is needed and why is it written on various sites, for example, and here I decided to place service programs for removing the printer absorber different models collected from different sources.

Actual models Canon printers You can also reset it using additional button combinations.

To use this program, it is necessary that the printer is in test mode,

1 Turn off the device (this is used for connections to a computer).

2 Press and release the Resume button, marked with a trikutnik near the stake.

3 Without releasing the Resume button, press the ON button (keep both buttons pressed).

4 When the power indicator lights up, release Resume and press twice, then release the offending buttons.

5 Run the program:

| iP1500 GeneralTool for Canon IP1500 | |

| IPtool 1.15 for canon IP1200, IP1300, IP1600, IP1700, IP1800, IP2200, IP2500 | |

| MPtool 0.96 for canon mp150, mp160, mp170, mp180, mp450, mp460 | |

| crkSTool_V1050 for Canon IP3600, IP4600, IP4700, MP190, MP240, MP250, MP260, MP270, MP480, MP540, MP550, MP620, MP630, MP980 from the service. | |

| Resetter Canon MP198 | |

| ServiceTool-aV7.00 for IP1200, IP1300, IP1600, IP1700, IP1800, IP1900, IP2200, IP2500, IP2600 (run crkSTool-aV700_no_port.exe) | |

| Servicetool_v1074 for IP2770 | |

| Servicetool_v2000 for IP3600 | |

| Servicetool_v3200 for MP280, 2140 and printers edition 2011-2012 | |

| Servicetool_v3400 for IP4900 and new Canon printers (the program was kindly provided by the correspondent) | |

|

Respect! Before using the program, make sure that your printer is not in the state of repair, only by cleaning the absorber and renewing it. |

|

Butt pointed Canon discount MP190:

Table of remedies for problems with cartridges:

|

LED Blinking (SFP) |

Error code (MFP) |

Message on the LCD |

Ink tanks/Cartridges |

||

|

Ink has run out. Move ink tank and close the cover. |

Replaced the empty ink tank |

CLI-8CMYBk, PGI-5Bk |

|||

|

MP170: CHECK INK MP450: Ink has run out. |

Replace the empty ink cartridge |

PG-40, PG-50, CL-41, |

|||

|

Ink tank not installed |

Install the applicable ink tank(s) properly |

CLI-8CMYBk, PGI-5Bk, BCI-16 |

|||

|

Multiple ink tanks of the same color installed |

Verify ink tank and location |

CLI-8CMYBk, PGI-5Bk |

|||

|

Ink tank in wrong position |

The ink cartridges are not installed. Multiple ink cartridges with the same colors are installed. |

Install ink tank(s) in the correct position |

CLI-8CMYBk, PGI-5Bk |

||

|

Multiple ink cartridge of the same color installed |

The ink cartridges are not installed. Multiple ink cartridges with the same colors are installed. |

Verify ink tank and location |

PG-40, PG-50, CL-41, CL-51 |

||

|

Ink cartridge in cool position |

The ink cartridges are not installed. Multiple ink cartridges with the same colors are installed. |

Verify ink tank and location |

PG-40, PG-50, CL-41, CL-51 |

||

|

An ink tank which has once been empty is installed |

Decreasing revenue from the upcoming ink cannot be correctly detected. |

Click Stop/Reset button for 5 sec or longer. The grinder will be turned on and the function for detecting theft ink amount will be turned off. |

CLI-8CMYBk, PGI-5Bk |

|

Note: If the phenomenon drops into several ink tanks at the same time, the operation will only be effective for the left-scale ink tank. |

|||||

|

Remaining ink amount unknown |

MP170: CHECK INK MP450: The following ink may run out. |

PG-40, PG-50, CL-41, |

|||

|

Remaining ink amount unknown |

MP170: CHECK INK MP450: ink cartridge once empty is installed. |

Click Stop/Reset button for 5 sec or longer. The grinder will be turned on and the function for setting the volume of shares for the frozen ink cartridge will be blocked. Note: Everyday ink-related errors will be related to the ink cartridge thereafter. |

PG-40, PG-50, CL-41, CL-51 |

||

|

Ink tank not recognized wrong destination |

Long lasting ink tank cannot be recognized. |

PG-40, PG-50, CL-41, |

|||

|

Ink tank hardware |

Long lasting ink tank cannot be recognized. |

Install the applicable ink tank(s) properly. |

CLI-8CMYBk, PGI-5Bk |

||

|

Ink cartridge not installed |

MP170: CHECK INK |

PG-40, PG-50, CL-41, |

|||

|

Ink cartridge not installed |

MP170: CHECK INK |

Install supported ink cartridge(s) properly. |

PG-40, PG-50, CL-41, CL-51 |

||

|

MP450: The ink cartridge attachment may be invisible. |

|||||

|

Ink cartridge not installed |

MP170: CHECK INK MP450: The ink cartridge attachment may be invisible. |

Install supported ink cartridge(s) properly. |

PG-40, PG-50, CL-41, |

||

|

Ink cartridge not installed |

MP170: CHECK INK MP450: The ink cartridge attachment may be invisible. |

Install supported ink cartridge(s) properly. |

PG-40, PG-50, CL-41, |

||

|

Ink cartridge not installed |

MP170: CHECK INK MP450: The ink cartridge attachment may be invisible. |

Install supported ink cartridge(s) properly. |

PG-40, PG-50, CL-41, |

||

When using the discount program you can receive the following:

|

Check item" Solution |

||||

|

Service function itself is available in the printer, however, the selected item (parameter) is not supported in the printer |

Aren't trying to set "platen" ink absorber counter though there is no "platen" ink absorber in the printer? |

|||

|

Is the destination you selected correct? |

||||

|

Service function is not available in the printer |

Should you install CD-R correction values because the printer does not have CD-R printing functionality? |

|||

|

Do you need to set LF / Eject correction values, so why does the printer not have LF / Eject correction functionality? |

||||

| V |

PC does not recognize printer |

Is the cable between the PC and the printer properly connected? |

||

|

Is the printer power turned on? |

||||

|

Does a distributor connect the PC and the printer? |

||||

|

Printer is not in service mode. |

What is the printer properly in the service mode? |

|||

|

Service tool is not applicable to the printer |

What is printer 2008 or later model? The service tool cannot be used in 2007 or earlier models. In 2007 and earlier models, you can select service modes via other buttons. |

|||

|

Aren't more than one printer connected to the PC? |

||||

| V |

The printer is in the factory mode. |

The problem is not to be caught in the field, because the pardon is indicated as a subsidy, so that there was no proper official participation in the enterprise. |

||

|

"Error 122" "Port Name Not Register" |

Too many ports are assigned by OS. |

What is Tool Service version 3.00 or earlier? |

||

|

The tool freezes. |

No communication with the printer |

Is there any error in the printer? |

||

Tamara, hello!

What is the absorber of a multifunctional printer device? This is a special sponge that absorbs, which is placed under the other head of the device. When the MFP is turned on or cleaned, the ink is pumped through the head of the device and drains from the sponge that is collected in the middle. Of course, through value hour There comes a time when the printer is damaged when the absorber can no longer absorb ink and is refilled. To be ahead of the Canon technology experts (our version has the MP160 model) about the problem that is pressing, and the main issue is the E8. If the indicator shows this code itself, it means that the liquid inside the absorber will not be sealed. As soon as the printer has informed about the E27 removal, the absorber of the processed ink has already been refilled.

The fragments of Canon's printers created an E8 grinder with a small reserve in the absorber tank, leaving the doctor of the same grade of ink to continue the normal operation of the MFP. However, this option is only suitable if the vinyl is washed first, the fragments in which you run the risk of completely re-filling the gasket that is absorbed, and in one way will prevent mechanical cleaning of the waste absorber at the service center.

To get rid of the doctor’s indications, follow the steps exactly:

- Turn off the devices before using the additional Power ON/OFF button.

- Press the “Resume” button and, once pressed, press the device again behind the “Power ON/OFF” button, but do not release it. In this way, you simultaneously release two buttons on the printer.

- Now, pressing the Power ON/OFF button, you need to release Resume.

- Press again on Resume for 2 rubles.

- Release the Power ON/OFF button. If at this moment the green indicator on the MFP is illuminated, then you have done everything correctly: the device is in service mode and is ready before entering orders.

- Pressing on Resume 4r. after sleep With skin worm pressure indicator that lights up I have to change my color: sometimes green, sometimes orange.

- Press “Power ON/OFF” 1 time to confirm the operation. discarding the doctor's ink.

- Again we press Resume as many times as it is necessary to select the required sub-function:

- Reset the level of the processed ink of the main absorber cleaner to the output value - do not press the Resume button (0 p.);

- Discarded amount of processed ink additional doctor absorber to the output value - press 1 press on the “Resume” button;

- Reducing the level of both the main and additional treatment of the processed absorber ink to the output values - click on Resume 2 rubles.

- Press the “Power ON/OFF” button 1 time. - start clicking on the selected subfunction (0, 1 or 2 clicks “Resume” at the first point).

- Press the "Power ON/OFF" button again to turn on the device.

More precisely, the implementation of this algorithm guarantees you a better result from the E8 reduction on the last term. However, I want to say that it is not wise to repeat this procedure twice: damage your MFP and take it to a service center to clean the absorber.

Thank you, Oleksandr.

One of the reasons that inkjet printers hang down to black is that the stench is likely to dry up as it gets lost on the paper. As a result, the ink dries easily in the nozzles of the other printer head. To clean dried ink in the nozzles, to reliably remove stains from the internal volumes of the other heads when changing the ink tank, printer manufacturers provide their own devices with different head cleaning mechanisms.

One of these mechanisms is a pump that pumps a small portion of ink from the heads and pours them into a container in the printer filled with material that absorbs the ink. Then, both the material that is collected and the capacity will be replenished by pumping ink from the heads and throwing ink into them. To replenish the capacity with pumped ink, the printer has a disinfectant that eliminates the amount of “wasted” ink and clogs the printer when the capacity is full.

This mechanism – the capacity, the absorbing material and the healer – is called diaper printer.

If healer of discarded ink waste ink absorber(or pad - klimok) counter collects the specified value (replacement diaper - waste ink absorber full), the printer shows a significant advance and seems to last for a long time.

The information is displayed in advance on the screen of the computer monitor to which the printer is connected, using the Monitor Status program (Status Monitor), which is included in the kit software security printer. Please provide information about those that the capacity for discarded ink is full or that parts of the printer have reached the end of their life and require replacement.

The printer itself signals about the diaper with a reliable light indicator.

Many “new” models of Canon printers inform about the filling of the diaper in series according to these indicators, which switch from yellow to green color, and with a clearly visible green signal as a series separator.

It looks something like this:

long green - yellow - green - yellow - green - ... - yellow - long green (and so on).

Yellow blinks between long green ones - SIM.

The older models in the series have SIX yellow-green blinks.

There is an indication of anticipation about those whose diapers are less than reliable. This series with all the pure yellow blinks: long green - yellow - yellow - ... - yellow - long green. You can continue running the printer for an hour beforehand by simply pressing the “Resume” button.

Shotguns Canon BJC 3000 / 6×00 / S400 / S450 / S4500, which are used by Koristuvach

The indicator blinks orange, after which the green color blinks once.

Note: before the process is completed, there are such exceptions, to remove them you do not need to enter the service mode and select any actions there; for example, when the “absorber may be new” message is detected, the paper feed button is pressed, when the cartridge is “shredded/wrong type”, the cartridge is changed, etc.

Cutters Canon BJC 3000 / 6×00 / S400 / S450 / S4500, which are not easy to use

The indicator blinks orange/green, after which it blinks once – green.

| Pardon ROM | 1 time | |

| Parcel RAM | 2 times | |

| Repair EEPROM | 3 times | 6800 |

| Setting the home position of the carriage | 4 times | 5100 |

| Temperature sensor reset | 5 times | 5400 |

| Absorber | 6 times | 5B00 |

| Temperature adjustment | 7 times | 5200 |

| Repairing the head temperature sensor | 8 times | 5200 |

| The cartridge is not identified beyond the position of your replacement | 9 times | 5600 |

| Removing the sensor of the paper supply system | 10 times | 5700 |

Note: in the third column there is an error code, which is displayed by the driver on the computer when you try to send the task to a friend.

Canon diaper discount

To improve the performance of the printer, it is necessary not only to replace the material that is being fed, but also to discard the printer. Removal of the registered diaper is carried out in the service mode of the printer by selecting a separate service function.

Many Canon printers are available for discounted service. Enter the service mode and select the service functions from the printer keyboard. Removing diapers for these printers, as a rule, is not difficult.

Diaper discount code for Canon Pixma printers

- Turn off the printer.

- Press Resume POWER button.

- While holding down the POWER button, release the RESUME button.

- Then press the RESUME button twice.

- Release all buttons.

The indicator blinks green and turns green. - Press the RESUME button 4 times to remove the diaper or any number of times you need to perform another operation. Watch the table:

- 1 time - Orange - Service test print

- 2 times - Green - EEPROM information print

- 3 times - Orange - EEPROM initialization

- 4 times – Green – Waste ink counter setting

- 5 times - Orange - Destination setting (Press Power > Press Resume 3x)

- 6 times – Green – Print head deep cleaning

- 11-13 times - Orange, Green, Orange - Return to menu selection

- 14 times - Green - Left margin correction

Turning on the ink healer that was lost in Canon Pixma

If, after refilling a cartridge, the printer complains that there is no ink in the cartridge - don’t get embarrassed! In order for the printer to work smoothly and without barking, you need to turn on the ink level control system in the cartridges once and again - press the flash button (middle, knitted on the mug) and hold for 10 seconds until the message appears on the monitor.

There are also a number of Canon printers in which the service mode does not work correctly every day - i320, i250-355, Pixma iP1000, iP1300/1700, iP1500, iP1200/1600/2200, , iP4200/5200, iP6000/8500; replacing the new one vikoristovat service program

General Tools. This varies depending on the printer model. Most of all, we grouped them together for their madness.

To enable the service mode functions of these printers, you need a computer running Win98, ME, 2000 or XP, a printer driver, a service program, and most importantly the printer itself.

Diapers can be printed on other brands of printers, for example, Epson, which is also necessary to contact additional service utilities. At any time, the doctor will need to re-train the printer until the printer is blocked.

In many new models Epson printers In addition to the R220, the value of the “diaper” cleaner, when it turns on and blocks the printer’s operation, does not have a constant value. The value of which type of “diaper” is used is chosen by the printer itself, both in the minds of its robot and in the selected range. From minimal to maximum possible. In this case, the value is greater than the maximum possible, and the “diaper” treatment has already been started. For everything, there is an algorithm for selecting the moment of application of the foundations at the next moment: the sooner the printer pumping mechanism is turned on, the more important the doctor can be reached, the first one will start. (The ink is vaporized from the kilimka, which is absorbed...)

Also remember that after 2-3 removals of the absorber, it is necessary to physically replace the gasket at the connection with it.

To collect diapers (absorbers) in advance, you can contact us at our service center.