Chernilo for string cartridges Divide into ink to remove barberry and ink to remove pigment. PIGMENT is a substance that is dispersed in the middle, but not separated into something else. KRASNIKOM - the speech is divided into the middle.

Quick-dry ink is an intermediate option. All the blacks are brought to us in the market as a center to wash the water.

The skin type has its advantages and disadvantages. Chornylo with barvnik

crushed from the surface of distilled radish or from detailed barn into powder in purified water. The scents are presented in a wide range of colors, the black is lighter and cheaper to create, and has lower pigments. However, the ink on barnberry has a tendency to be absorbed from the fiber of the paper. The stench is strong enough to bloom, which can lead to problems with capillary sealing and spilling of the farby, as well as to a more liquid bloom of the farby.

Ink on pigment represent the dependence of particles in size per micron in size (dispersion). These small crystals become light and stick to the material. The pigment sticks to the paper, lower barvnik. As a result, the pigment was given more lightness and color, and was more beautiful for archival purposes. However, the dispersion in pigment inks makes the nozzles more subtle to the point of laughter, and the lower ink on the barnberry. This makes the cartridge head nozzles wear out more quickly and become noticeable.

When refilling ink cartridges, it is important to know which cartridges to refill with pigment ink, and which ones to refill in the printer. Inodi original ink are lost in cartridges that need to be refilled or cleaned. If the pigment is poured into a cartridge with ink on the barnberry (or inadvertently), the new ink may react with the old one, having been changed in a chemical warehouse, which can cause the cartridge to break down. There are special inks that can be successfully used in all kinds of minds. Detailed information can be obtained from the ink supplier.

The greatest collapse occurs when the cartridge is reanimated after the pigment ink has dried out. After the ink is dry, you can easily remove the cartridge by adding ammonia to the water.

Zagalom, which means that the other head has dried up, can be seen behind the offensive sign: if clean leaves come out when you hand it, it means that the head itself has dried up.

If you put ink on the barnberry, then the stench will be taken away by the original water. If water doesn’t help, it means you’re confused. Make sure you no longer trade on the ink of this company.

Updating heads on inkjet printers from Epson

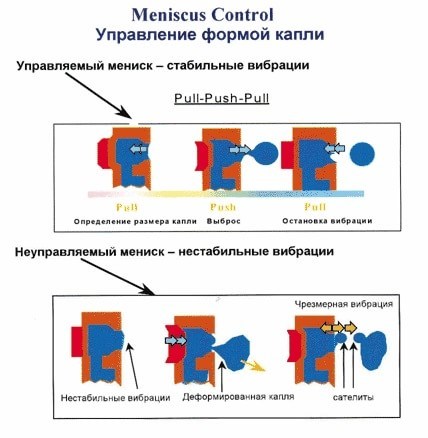

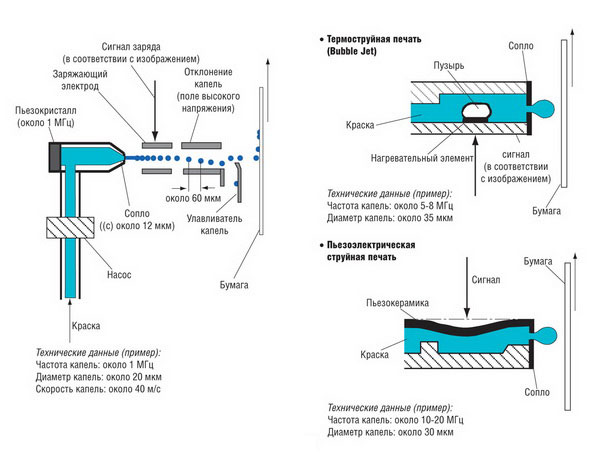

Epson has adopted the principle of stamping ink drops; Like the piston, the power of the piston element changes its shape when voltage is applied.

The advantage of such a device is the ability to place the nozzles even closer to one and give up a great deal of space for the device. Not enough - very high vymogi until vikorystovana ink (due to the flatness, dispersion of barn, the time of drying); as an inheritance - the quality of this ink is high. That is why the koristuvachs are trying to vikoristivate the ink of other virobniks.

To change the ink quality, Epson's competitors are making the technology cheaper; It is possible that the parameters cannot be changed. And the result is obvious, or more precisely, at the head (of the printer): the nozzles become clogged, the ink itself dries out.

Rada Persha- vikoristan ultrasonic bath for washing the head. Without having done any research myself, but having worked hard to get the hang of it, you need to find a bath or buy it, then experiment with the printer head (the depth of water, the time of soaking, the warehouse of the garden), and if you have one printer (let’s say, a home one), then some short-range experiment will lead to the output of the head (and the printer) going well the next day. Are you fooling around?!

Happy friend- Washing the head under a pressure.

The technique is as follows: fill the syringe with radigin to cleanse the head and gently press on the piston, trying to break through the nozzles. If the nozzles are not too dry, this method will help; and if you don’t - lose the elements, and - goodbye, head!

Method three, try it out especially. Based on the same method as recommended by the printer itself: a vicor pump, which is found on all Epson printers.

For the cob, we stock up on a sufficient amount of radish for washing the heads (0.5-1 l), since the larger the packaging, the cheaper it is to get one volume of radish. Then we frequently disassemble the printer so that the parking node can be accessed. We press the head out of the hole and drip it onto the foam rubber at the parking joint, turn everything in place and let it soak for a few years. Turn the head more quickly when the printer is turned on, so that the pump does not pump out the area for washing - it’s too early.

Then we soak the printer and allow it to carry out a cleaning cycle. Another checklist. If the result is unsatisfactory, we prepare a bunch of syringes (or less in volume - by 2 ml) and cut off the upper part of one syringe. Fill the syringe with foam rubber, remove the cartridge and press the ink onto the syringe instead of the cartridge. We fill the syringe and give the printer a number of commands to pump; can be wrapped; Then we turn the cartridges in place.

Sometimes I pour ink into the cartridge itself (2-3 ml, close to the suction cup) - the ink in the cartridge still dries up. Then I give the command to pump with this ink - and that’s all, in 90% of cases this technology helps.

Since the described approaches still did not help, we remove the head and try to rinse it with a syringe, but the main emphasis is not on squeezing out the dried ink (those that were broken by the pump), but on soaking up the ink from the head. As the result appears - let's say, 70% of the nozzles are used - a very original ink: it may be left to clean those that were not given to us.

And then we put crazy ink- and save, save, save (until the problem appears again).

Unfortunately, the original was not a panacea for all sorts of ills: it just dried up in the nozzles, like crazy - for example, it went at the outlet, and hello to the head; the problem is solved for you.

And now about the sum: Epson retailers don’t sleep, they’ve started a stink in the production industry polymer ink DURA Brite , which do not wrinkle, do not bloom. And if the stench has dried up in your head, you will have to wash your head completely.

Okremo - about discarding the doctor and renewing the absorber

(When wearing "diapers").

I recommend starting and finishing all work with this procedure; and if there is a need, then remember it yourself from the dispatcher.

What vikoristovuvati yak naponyuvach? The scope for imagination is the greatest: from the original to medical cotton wool.

Well, if the diapers stuck, then we can talk about preventative maintenance of the printer.

Prevention of mechanics inkjet printer there is little benefit in the prevention of matrix; Only here, perhaps, there will be more rubbish - so pour or splatter the ink and rub the paper. All at once gives a “monstrous” result: the brood is coked in the mechanics right up until the printer comes out of order.

Regarding the selection of oil for the guide, I will tell you in advance: ideally you need oil for precision mechanics (the right oil); Previously, government stores sold oil for sewing machines - just like that. Nina can really buy and zbroyova oil.

For direct ones, you need to change or wash the outer rings or gaskets (depending on the model).

Okremo I'll say about the parking lot of the head

. About the foam rubber near the parking lot, which needs to be changed, I have already said more, but it is obligatory to put the respect on the gum, which is pressed to the head: it is not the fault of the brute, so that the pressure of the yakomog is more intense - then Trivalom saved The ink began to dry up later.

Particular respect is given to the bottom that cleanses the head: there is also ink that has dried up.

As a final step, you can use the center for internal rinsing. Epson cartridges(call the yellow color). By pouring the leftovers into the cartridge to soak the radish, you can try filling the entire cartridge with the whole radish. After updating and washing, pour a special liquid into the cartridge (T013, original), let it dry - the brightness and color are still good. And if you remember that the ink that goes into the cartridge is not so rich, then as an alternative to the original refills and ink, the original ink is almost twice as cheap.

Now about the nuances: refueling must be done very carefully; I tried it on low-capacity cartridges (a cartridge without sensors, chips and other accessories - they have their own specifics). Having verified the significance of the text; Perhaps the black color is not suitable for photos.

Epson head cleaning method

- When rinsing, do not apply pressure to the nozzles (on both sides); The best way to do this is to do it this way: without losing your mind, place the cotton wool with the meat or in the middle of the pan so that the edges of the gum overlap it; Pour some water in there so that the bath runs again.

- Park the head manually, and pull the animal's tubes of the same diameter onto the rod. At the end, tighten the syringe (with a plastic, not a gum piston) with a flush line - OBOV'YAZKOVO, fill the syringe, fill half of it empty (there may be a damaged pillow).

- Lightly press on the syringe (if the syringe is 10 ml, then the volume will be 5 ml and 5 times, and pressing it at 0.25 times will ensure a slight pressure); fill it in for 3-24 years in this situation. Monitor how things are going - if they went straight away, then there is nothing left to worry about.

- Then remove the head and control the passage of the ink, the particles breaking the piston (on the same floor): in an ideally positioned head, 10-15 centimeters of ink will flow from the nozzle; and you, melodiously, if it’s ice-ice, you won’t be able to wake up normally anymore.

You can’t press the nozzle - you break the crystal: it’s too thin; The smallest crack - and you won’t notice it - then, after about an hour, let the ink flow onto the back of the crystal and that’s it!

Respect!!! Do not allow the home to be wasted in the same place, the train will be released. on the gate side of the crystal (and fee, obviously). If it’s still worn out, let it dry for a long time until it’s completely dry - there’s a high-frequency voltage, and it’s going to burn directly under the influx and, like acid, everything instantly goes rosy!

They seal this opening (carefully, with silicone) - that’s right, the water won’t leak there anymore, and there’s nothing to repair there; When washed, the head can be lowered deeper into the bath without fear.

I recommend silicone tubes, you can use the old Epson - they have a mild stench, and, smelling, dampen the pressure of the nozzle (the protection is like a fool). I recommend installing syringes in a self-made hanger above the printers - I have long tubes and hang on the station in the grooves.

Then do not forget to install the original cartridges. I, having squinted at the nozzles, pumped out a little bit of ink - leather color - I wouldn’t be able to live without it. So then use these cartridges and install them in place.

The simplest thing is to shy away from a used Epson; I have a home-made vacuum chamber with suction cups, made from a gum balloon inserted into metallium; And the central compressor will pump again. Zagalom, pumping is carried out with a home-made suction cup onto a syringe.

You can go about pumping and it’s simpler - remove the cap from your Epson (in case of any accident, so as not to spill the diaper, take the tube out of it - and away). We park the head (or just put the cotton wool in the suction cup, and pour it into the middle - there will be no need to see it again). And we simply wrap the gear with the left hand, whichever is closest to us, up there. So, for the paper supply shaft to turn “backwards” (backward), pump the pump more, and watch the tube: there may be a lot of ink coming out.

Cleaning other Canon inkjet printer heads

- "Mr. Muscle for Mitty Skla with Ammonia" (hereinafter "MM"), produced under the license of "E.S. Johnson" (original emerald green color, sold in almost all government stores and convenience stores).

- Respect! Don't forget to read the warehouse! We are called "MM", a warehouse of which: isopropyl alcohol, aqueous ammonia, ether ethylene glycol, STEAM, aroma, barnberry.

- Vata - m'yaka, without breasts. Most often, these authorities use sterile medical cotton wool, purchased at the nearest pharmacy; 50 grams to grind more than one other head.

- Water for injections 100 ml - this is distilled water that has not been salted by reverse osmosis. Medicine serves as a warehouse for the preparation of medicinal drugs and injections; Sold in pharmacies as ampoules for approximately 50 rubles for 10 ampoules of 5 ml. In this case, it is expensive, so it is recommended that you get it in prescription departments of pharmacies, medical dispensaries, LPPs (medical and preventive clinics, clinics), doctors, sanatoriums, hospitals, etc.

- A plastic mold for installing a PG in it with a pedestal with nozzles (further a bathtub). You can reliably press the form into margarine, top butter, cream cheese, etc.

- Polyethylene bag; size - so that a bathtub can be placed at the same time as the steam generator and it can be tightly closed to “enclose” the outside environment. It is advisable to manually lock bags.

- 2 medical syringes with heads, volume 10-20 ml.

- Quick-fading paper servettes or a roll of soft toilet paper (surprisingly, it’s handy), for example Zewa.

- A hand-held hair dryer for drying hair.

Washing process:

- Rozdrukovovo is a roll of toilet paper. We drill 5-6 sections of 1-1.5 meters each. Fold in a number of times to trim a width of 4-5 centimeters, equal or a little larger than the bottom part of the PG.

- We install the PG (in weight, without cartridges) with nozzles on one of these toilet paper paper strips in order to remove excess ink from the PG. If necessary (there is a lot of ink), we replace the toilet paper paper with a new one. We repeat until the documents on the paper continue to lose ink from the nozzles.

- Having lightly moistened with "MM" the pieces of toilet paper that have been folded several times, carefully, silently, we wipe the entire surface of the other head, behind the screw of the electrical controller board and the intake fittings (the place where the cartridge is pressed D) until then, until you everything is clean.

- We take a syringe from the neck and draw it into the new “MM”. From any stand, thoroughly rinse the PG collection fittings with a syringe until the excess ink is removed.

- Having unpacked the medical cotton wool, we wind the rags of such a size so as to completely close the park fittings, and at most PGs evenly around the fitting. Carefully, without making any noise, we place small pieces of cotton wool on the intake fittings. The soul is soaked with “MM” all this cotton wool until the hour when the country inadvertently leaves the PG.

- Carefully install it next to the PG bath with nozzles down.

- Heat "Mr. Muscle" to a temperature of 40-45 degrees (not too much, but with butter - for quicker rinsing).

- We pour “MM” into the bath until the rhubarb is 2-3 mm thicker at the nozzle.

- We take the bath from the installed PG from the polyethylene bag. Close the package tightly.

- We allow in such a camp a minimum amount of downtime.

- Through the addition, we change the size of the bath, remove the cotton wool and repeat the 4 steps in front. I’m calling for more.

- Through the addition, we remove PG from the bath and change the cotton wool to a new soaked one. Up to the nozzle, the folding of the toilet paper is pressed down - it is possible to naturally pump "Mr. Muscle" from the parkan. We repeat this operation until we apply it on a new piece of folded toilet paper with a clean "MM" paper without any ink.

- We fill a new (or after “Mr. Muscle”) syringe with injectable water, rinse the PG from excess “MM”, including electronics, because You, of course, have come to the point of soaking in the “MM”, and repeating the previous point, after the fact, that the cotton will already be leaked with injecting water. Repeat pumping until you have used up approximately 4-5 pieces of folded toilet paper. The result on the paper (on the 5th paper) is due to the lack of clarity in the nozzle selection.

- Let's remove the cotton wool. With a toilet paper, we collect water from the intake fittings and around them. Let's fold the excess water with a piece of toilet paper. Carefully, without even reporting, we wipe the entire head.

- Turn on the hairdryer and place a dry steam generator on the stand (so as not to overheat), especially the visible electrical part with a length of at least 30 cm.

- New or refilled cartridges are installed into the PG printer (when refilling, fill in good ink, type InkTec).

- From the computer using an additional printer driver (if the computer does not have a computer, then from Service Mode), it is necessary to do at least 2 deep cleanings of all cartridges.

- Let's wait 30 minutes and test the nozzles thoroughly.

P.S. : I specifically did not use the vicoristic “capsules” on the intake fitting of the hydraulic head, because I don’t buy any special items due to idle time.

P.P.S. : Of course, after trying dozens of products, the InkTec Cleaning Solution (especially when the pigment cartridge was heavily stained) did not turn out to be better than the “Mr. Muscle” category.

P.P.P.S. : in particularly important situations (reactions of various chemical deposits of ink), you can use an ultrasonic bath at your own risk. If you need to soak it, put 5 quills in an ultrasonic bath with a pressure of 40W, which can be applied to the dental head.

Cleaning the drive heads of HP and Lexmark inkjet printers

HP cartridge fragments are monobloc, so they are easier to wash, but they dry out faster. Zagalom, more over-infused materials can be frozen up to HP cartridges.

Use internal rinses (pump with a syringe through the foam of the cartridge) and external ones - for soaking the heads in the baths. It is permissible to stagnate the tipi. All ink for HP black cartridges is more pigmented, so rinsing is also the problem for pigment ink. Color cartridges are non-pigmented.

Your cartridge is leaking

There are only two reasons why this cartridge may leak:

- Renewal cartridge. Remove the ink from this paper or allow it to flow freely to achieve completeness.

- The bottom of the cartridge is damaged. Such damage is clearly evident when you look at the cartridge. It’s better to throw away a damaged cartridge.

If your cartridge does not work

If your printer, after refilling, does not recognize the cartridge as full and only refills it as empty - this is also possible on some types of HP printers, then you can speed up the operation of resetting the cartridge codes in the printer. Detailed instructions You can find information about the discounted operation here. This is just a wet cartridge - just a box filled with foam rubber. Try this:

- Make sure that the ink has completely seeped through the sponge to the bottom of the cartridge. If the foam rubber does not seep through, the cartridge will not be damaged.

- Follow the instructions that came with the printer in order to start the head nozzle pumping operation. This operation is launched by the program from HP Toolbox.

- If this does not help, go with the cartridge to the nearest water tap that contains hot water.

- Turn on the water. Wait until you're out there in the hot water.

- Place the cartridge with this piece on a different nozzle (so that the ink comes out) under a stream of hot water for 2 or 3 seconds - NOT 10 seconds!

- Dry the cartridge with a soft towel.

- Re-insert the cartridge into the printer.

- Start the operation of cleaning the nozzles of the splint head once.

Oleksandr Dudkin

. Company Ink-Market

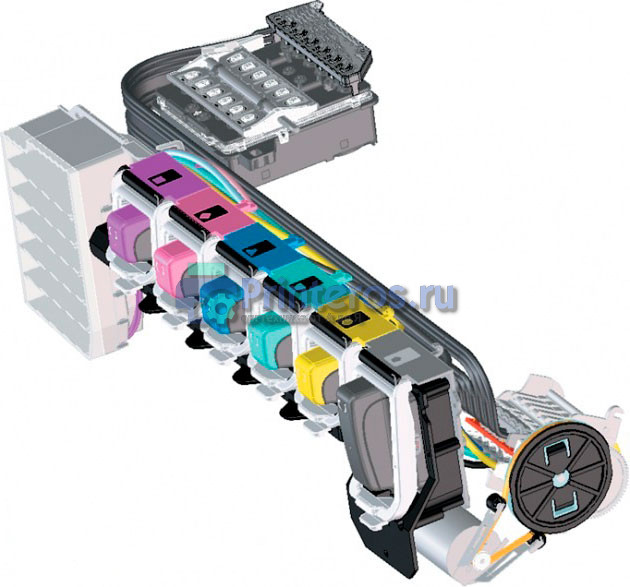

Jet printer with embedded CISS - Epson M100

The secondary head of the device is equipped with a number of microscopic openings, called nozzles, or nozzles, which allow the paper, plastic or other material to absorb the ink. The PG moves along the unshakable leaf, without sticking to its surface, and sprinkles with specks of barnberry.

The concept of an inkjet printer appeared in the 19th century, and in 1951 the Siemens company patented an inkjet printer based on continuous ink supply technology (Continuous Ink Jet).

The method will be carried out on a permanent basis through the nozzles of a high vise with a pump. At the level of the nozzle, the jet of ink is broken up into silent specks of acoustic flux, which is created by a piezoelectric crystal. Immediately, the droplets that are innocently deposited on the paper are absorbed by an electrostatic system and returned behind a special reservoir. In the process, a very small number of specks are vicorized, and the main mass is rotated for repeated vicorization.

Technology may sing accomplishments:

- the nozzles do not dry out, so that the blackness must pass through it gradually;

- the force of the droplets is great and is possible for a significant distance from the drill head to the paper;

- Adding summer ink to the warehouse allows the droplets to fly to the desired location and dry quickly.

Such printers continue to be used in medicine as recorders, and in industry – for labeling goods and packaging. Ale stinks and smells not enough:

- The bottle, which enters the ink warehouse, is vaporized during continuous circulation through the nozzles and turned behind a special chute, and the liquid becomes viscous, which requires constant control and dilution;

- Printers are bulky and even expensive.

Tribute to Vimoga

Printers from Siemens, Canon, and HP have been developing technology for a long time, which makes it possible to create a printer that is not so foldable or large. The truth is, as they wanted to believe, it is not enough to allow drops of ink to pass through the nozzle only unless absolutely necessary. All three teams achieved success.

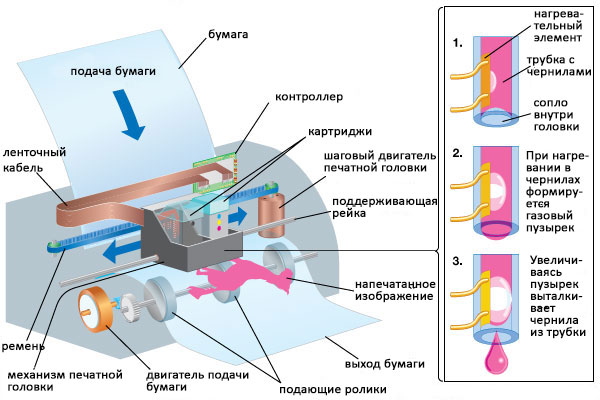

Siemens presented its first printer, the PT-80, in 1977. Following the advanced technology, drops of ink were spent on the paper at the required hour with the help of piezoelectronic tubes. Two years later, the Canon company completed the development of a method for heating barnacles with thermocouples and called it BubbleJet or the method of gas bulbs. HP completed the project almost overnight, emulating the same principle in its research. But the technology is much different and, naturally, the team guessed a different name: drop-on-demand.

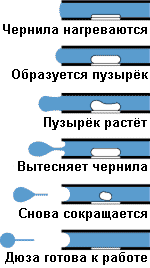

BubbleJet

The method is primed on short-circuit thermal elements, which heat up to 500 °C when an electric current passes through them. The ink is boiling, the gas fume, which is dissipating, squeezes out a speck of farbi through the nozzle. Once heated, the bulb falls and a new portion of barnacle is added to the chamber.

High brightness for other text, lines, histograms, and even further expand the graphic images in the area of the surface, it is clear that there is a breeze that flows from the nozzle, accompanying the main drop of ink. The thermal operating principle of the inkjet printer allows printing to reach the warehouse:

- the complexity of the materials used for the production of other parts of the mechanical head;

- water base, which allows the gas bulbs to harden;

- It is important to control the heating temperature and not to become irritated, soot deposited, or scorched.

Drop-on-demand

The heating element is located directly opposite the nozzle, the gas bulbs collapse in line with the ink, and do not appear to be pressed down like with the BubbleJet method.

This is not the same thing. The heating of the thermoelement is then heated to a temperature of 650° C, which causes it to boil and flow through a nozzle in a gas-like state. Such mistakes result in clearer results in the field of natural filling, which is clearly matched by the technology of gas bulbs.

The disadvantage of both methods is that the other head will quickly come out of fret due to the fact that it is stable on the part at high temperatures. The size and capacity of the heating system are small, which allowed generators to use a GHG cartridge. Residents are advised to remove the dispenser after finishing the ink.

Most people can refill cartridges on their own or install CISS, unless the check head is particularly durable and cannot be used manually. Owners of thermal inkjet printers from Canon, HP, Lexmark are especially careful to carefully watch the ink line. The barnberry itself acts as a medium that cools, and with an empty PG cartridge, it singly comes out of tune without the possibility of renewal.

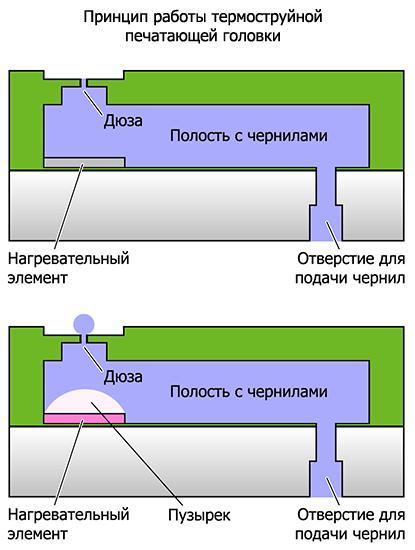

P'ezoelectric method

The Epson company has developed a high-power technology based on expanded crystals under the infusion of an electric stream. Having lost the impulse, the element is deformed and forces the vibration plate or diaphragm to press against the ink chamber, pressing droplets through the nozzles. In this case, the temperature does not change significantly, which coincides with the term of service of the mechanical head. It is important that the fragments of the PG are foldable and have an invisible part of the device. Of course, with any inkjet printer, the other head may dry out because it has not been used for a long time, or the cartridges were filled with the wrong ink. However, for Epson printers, the possibility of successfully updating a part is even greater.

The color image is clearer and has more contrast, due to how the inkjet printer uses a petroelectric ink supply circuit. Immediately after inserting the membrane of the droplet through the nozzle, a tensile pulse is applied to the crystal crystal, which causes the vibration plate to bend in the reverse direction. The ink chamber becomes larger, which allows you to not only let in the next portion of farbee from the cartridge, but also to pull back the ink that goes behind the drops and prevents the creation of the satellite drops. The very same scheduled flows of ink that follow the main wiki, will easily dissipate other modern graphic images with thermojet printers.

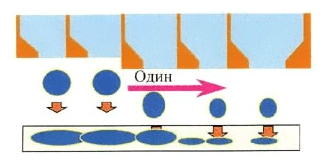

The quality of other photographs moves when the spots change. For thermal heads, this is determined by changing the nozzle size. For piezoelectric technology, the diameter of the nozzle is not important; it is enough to control the force of the jet in order to ensure a consistent flow of the barn. Each image with micro-drops 1 picoliter in size, as printed on thermal inkjet printers, takes many hours.

P'esotechnology allows for the production of droplets of different sizes if necessary: for other areas of effective filling - large, for other parts or linings - small. In one pass of the carriage, droplets of three sizes can be removed, which significantly increases the fluidity of the hand.

The production of a piezoelectric mechanical head is much more expensive than thermal one, but this technology makes it possible to ensure long term service and high intensity to the hand.

Be friendly with your satisfaction.

People most often choose inkjet printers for their home or office. Such a device, as a rule, costs a little less, and is less laser-based, but it doesn’t sacrifice anything for the price. In order to understand whether such a device is suitable for your needs, it is important to understand the operating principle of an inkjet printer.

People most often choose inkjet printers for their home or office. Such a device, as a rule, costs a little less, and is less laser-based, but it doesn’t sacrifice anything for the price. In order to understand whether such a device is suitable for your needs, it is important to understand the operating principle of an inkjet printer.

The circuit diagram of inkjet printers is simple. The paper tray drains the middle of the printer. The computer transmits information about the text and images to the format board, which uses another head and ink to print them on the paper. Sometimes, immediately after dismantling, the papier may lose some of its moisture. Some producers install a special heater to remove this shortfall.

If you look at the over-the-arm picture through a microscope, you will notice that the entire document consists of small speckles of farbi. The diameter of the skin is ten times smaller than that of a human hair. The principle of the hand maker is based on a spray of fine particles of Farbi, which forms a letter or symbol.

Now you have to learn about this, how the other inkjet printer works. Other heads have many different openings, called nozzles or nozzles, and their number can number in the thousands. Through them, under a pressure, a farb is inserted. At the same time, through special channels, all colors of ink are supplied to the nozzle, but only those necessary for the creation of information are selected, and those not required are sent for secondary use. This approach gives the channels the opportunity to be productive in the future, as they often stagnate with only one color.

The creative head can be installed in the middle of the printer or connected to the cartridge. The placement of this element infuses fluidity into the arm of the inkjet printer. As the head is installed in the device itself, the fluidity level moves significantly. And the equipment, the price of which is 60 arkush per piece.

People appreciate that the placement of the head in the printer reduces the cost of replacing cartridges. But in practice this is not at all the case. The price for a cartridge with this element is practically identical to the price without it. Virobniks are obligated to include in the product description the location of the drill head.

How ink is fed

Since everything is clear about how the inkjet printer works, how to start working on your work is no longer a mystery. Now let’s figure out how the little ones are created. The strumenevy arm can be thermal or electrical.

In the fall, when the thermal jet is hot, the ink boils under the influx of heated water. electric strum element up to 500 degrees Celsius. At this time, the bulbs from the furnace are formed and the pressure on the ink chamber increases, as a result of which speckles are visible through the nozzles. After this, the pressure in the chamber is reduced and an additional portion is added there. This method is called BubbleJet. If the temperature of the work is high, then the ink is sticky and water-based, so that it is not burnt and does not remove carbon deposits.

Thermal technology also offers another method called Drop-on-demand. This element, which helps the furnace to heat up, is located opposite the nozzle, which allows the bulbs to collapse in one direction. Heating is carried out until the 650 degree mark, which allows you to create not a bulb, but a cloud of steam from the farbou. In this case, the picture is very clear.

The cutting head with thermal technology immediately stops working through a steady infusion high temperature. In order for it to last longer, you need to control the heat of the farbi, so you need to cool the head.

The piezoelectric jet arm generates thermal energy between the heating element and the ink chamber and a special diaphragm. The crystal, when heated, pushes the diaphragm, which removes the ink from the camera. After this, the plate moves at the gate, spluttering breezes that can freeze the picture.

With this additional technology, you can adjust the size of the speckles that will be released from the nozzle, which is even handy for photo printers, where the streamer is removed, the fragments of the speckles make the image clear and bright . The fluidity of a piezoelectric arm is an order of magnitude higher than thermal.

Now you need a cartridge

The cartridge is a container that houses a small amount of food. Inkjet printers can be equipped with both combined and separate cartridges. Combined with a red, blue and yellow farby. In most cases, the skin color is determined by its cartridge. For a black color, a vicor cartridge is used. Replacing the combined (tricolor) cartridge is necessary whenever one of the colors runs out. It is necessary to work out how other colors are enough, which is not economical.

If the device is left idle for an hour, the ink in the middle of the cartridge may dry out. Virishity Qiu problem There are many options available for help. First of all, buy a new one. In other words, they will turn into fakivtsy, trying to renew their productivity. Thirdly, you can do the same thing as the fakhivtsi budinka by reading the article about those. For this you need distilled water or a special medium for washing cartridges.

Cartridges for these devices are small in size, which means the capacity of the farbi in them is very small, approximately 13 milliliters. I'm going to grind it out in order to cut out about 400 paper sheets of A4 standard paper with 5% padding. Therefore, if devices are used very often, for example, in the office, then cartridges are often replaced. In this case, it is necessary to install a continuous ink supply system (SNPL).

This design helps to significantly protect the scraps, if ink is drawn out of the container, you just need to top it up, and not replace the entire structure. This can also be done by changing the ink in jet printers. When replacing the cartridge every time, a part of the farby is removed for cleaning, and if the device signals that the ink is finished, then the capacity is filled to 10%. Currently, many other devices have begun to produce printers with an integrated ink supply system. Such devices are much more expensive to purchase for printers with replaceable cartridges, but they are much cheaper to operate and cost much more consistently for printers with Chinese CISS.

tipi black

Water-resistant and pigment inks are used for the string instrument. The rest are wonderfully suitable for drawing pictures high vigor Therefore, devices with such frames are installed in photo salons or on photo booths. The ink is water-based, except for the barberry, there are components in its storage that help the ink to easily permeate the paper, get stuck in the new, barbed fibers and even dry out quickly.

The Strumenevy printer is built to wrap the color picture, stand up to mechanical problems, good juiciness. The only thing such destruction is afraid of is water. When the picture or text gets wet, it becomes sealed.

To differentiate the entire palette of shades, the following colors are used:

Zhovtiy;

blue;

purple (red);

black

This spectrum is sufficient for a variety of nasty pictures in home minds and even photographs. To create brighter, brighter images, the printer for other photographs should be equipped with a palette larger number ink. For example, add light blue, light purple and other colors.

It would seem that from the three assigned colors you can create black. In practice, there is no such way to remove black color stains. This can be done with the unsatisfactory mixture of barberries for creating ink, or by pouring in other substances that are added to the ink so that it becomes more stable and drying. Therefore, the jet printer uses a black cartridge made of black tar paper.

Paper feeding method

The printer can be mounted vertically on the device - the feed tray is located in the opposite direction, or horizontally - the tray is located in the lower part. The paper transfer device of an inkjet printer picks up the sheet behind the help of a roller with gum pads. To ensure that the paper does not move, the additional roller is also made of gum pads. Regardless of the filing method, the orientation can be either portrait or landscape.

It is necessary to stitch so that the paper feed tray does not get caught by foreign objects. Otherwise, the leaves will wrinkle, sag unevenly and become brown. The device may be zipped.

Functional devices (MFPs) continue to be very popular among buyers. This attachment combines the functions of three attachments. On our website you can watch a video review of the model and decide to look for the required characteristics.

Important moments

Having become familiar with how the printer works, you can make the following ideas: Regardless of simplicity, printers that work with printers can effectively separate both images and text documents.

- Choosing between thermal and piezoelectric technology, you need to use the same method to add a device. If you need a clear picture, it is better to choose piezoelectric technology.

- In order to ensure that the farb does not dry out, even during periods of inactivity, it is necessary to separate one miscellaneous side per week.

- The jet printer is ideal for use at home during infrequent and not very intense use.

- For better use in offices, it is easier to install CISS and the problem with frequent replacement of the inkjet printer cartridge will be removed.

On the butt of an inkjet printer EPSON Let's take a look at the attachment of the other head today. In addition, a piezoelectric head is installed in the printer and performs the entire service life of the printer, and the plastic cartridge-ink axis, as a waste material, is changed or refilled during operation.

This scheme has its pros and cons

Pros

- High intensity of the hand

- Extremely inexpensive stained glass materials

Minuses

- Expensive repair of the mechanical head

- During long periods of inactivity, the head needs to be cleaned, which wastes ink.

The skin owner of such a printer, melodiously, felt the need to reduce the cost of operation and not buy new cartridges, but refill old ones. If you are more afraid of the process, then your head may start laughing. acid ink And you will have to spend a lot of money on repairs at the service center. I hasten to please you, it is still possible to safely refill these cartridges, but for this you need to use clear ink. There are already a lot of different refueling kits being sold at different prices, most of them are manufactured in China, and there’s no need to talk about their versatility. Not only does your hand strength become significantly lower, but there is also a chance of not losing the service center without a job. I'll be honest, I've never bought anything original cartridges😉 I use InkMaster ink for refilling ink (don’t respect the advertising 😉, they are prepared in Germany and England, and for the Chinese they ensure excellent quality of the hand and saving of the drill head, I want to cost more money. Also, sell non-original cartridges instead of vikorystvo. I don’t want them, because I don’t know what’s going on there. EPSON printers And why can things go well?

Attachment of the drill head

Well, then, you don’t harm the docks, you don’t understand the structure. Let's break one other head at once (the color one of the Epson Stylus Color 200) and figure out how it works and what goes wrong (I don't think that you have any intention of doing this with your printer 😉

MANUAL HEAD BLOCK

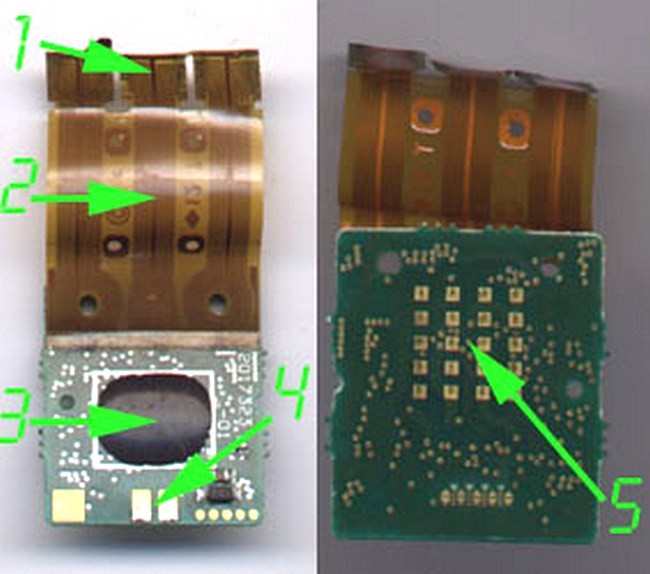

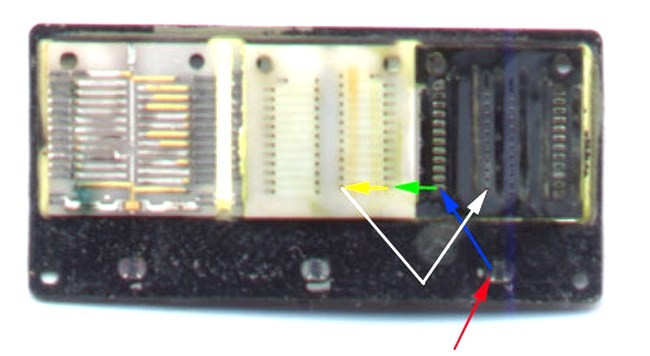

In the photo, below the readings, the block of the hydraulic head is removed from which the control board has been removed. U various models In printers, the design of this unit can be removable (this printer has a loose unit; in older models it cannot be removed without twisting.) To this stage, you can disassemble without using destructive methods, then you will need to fix them.

![]()

1 - Krishka;

2 - Cartridge visibility sensor;

3 - place for payment;

4 - A place for another university.

BOARD WITH LOAD

The photo below shows the board with a cable that connects to the electrical elements.

1 - contacts that go to the electrical elements;

2 - train;

3 - ceramic microcircuit;

4- contacts that close when the cartridge is inserted;

5 — contacts for connecting the manual head unit to the printer)

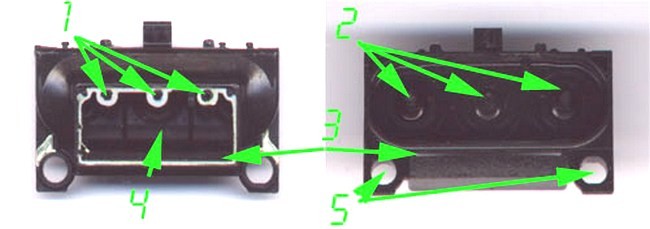

OTHER VUZOL

In the next photo of the readings, there is another ink, in which another element is installed, the channels of 1 ink from the cartridge go into the other element, whose device can be seen further. The photo shows that the joint is glued with a special glue (white), and this glue can be easily dissolved with alcohol, acetone, etc. this chemistry It is NOT POSSIBLE to clean another node!

1 - ink channels;

2 - tubes, through which ink is removed from the cartridge;

3 - gap for the train;

4 - place for the other element;

5 - open to attach another node to the block.

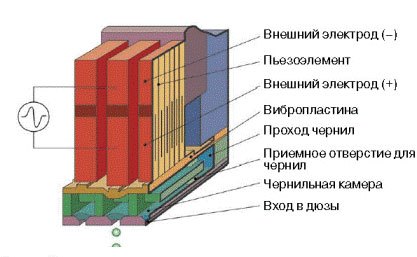

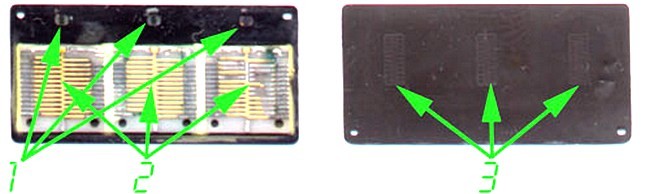

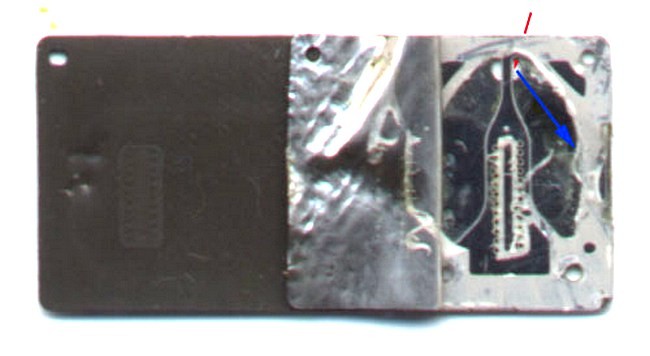

OTHER ELEMENT

In the photo below the indications there is another element. There are 3 glued metal plates, and plastic elements are glued to them. The ink, having flowed into channels 1 from the other node, is lost into the piezoelements, which are discharged through nozzles 3 onto the paper. Let's take a look at the device of the other element in the report, for which we place a ball on the side of the nozzles and glue one plastic element.

1 - ink channels;

2 - electrical elements, a cable is connected to their contacts;

3- nozzles, from here it started to fly onto the papier.

In the next photo of the testimony, the other element is removed and turned upside down.

In the photo below - with a bent outer plate. The arrows cleverly show the direction of the flow of ink: red - ink sinks into another element, blue - sinks into the ink element, green - sinks into the element, yellow - accelerates into the element, white - violet from the element through the nozzles onto the paper.

The other head of EPSON inkjet printers is a very foldable device, there is a lot of space in it that can get dirty, so I don’t recommend using unclear stained materials. When the clear ink of everyday problems is stuck, there is no need to blame, but it is also possible to clean the other head using special methods. But it’s a completely different story.

P.S. Thank you for the not very clear photographs, so I asked them for emergency help flatbed scanner. It turns out that the scanner can scan only a few papers 😉

Popularity: 4,935 pp.